All of us know the importance of packaging. And every product is important for a business owner. Therefore to protect them from damage and abrasion it is more than essential to pack them safely. Unitizing and palletizing multiple products can be a challenge for many businessmen. But Clear pallet stretch wraps offer maximum protection. They help in unitizing several items during transit. If not for these, there are numerous risks that a business would face, including the damage of reputation. A good reputation is essential for every individual. It is even more important for a brand because apart from gaining respect, a good brand reputation is a help in boosting your business. Bad packaging can have a negative impact on your brand. Your current clients and prospective ones may think that if you haven’t taken too much effort to protect your item, then the quality of your item may be bad. So amongst all the other packaging materials, stretch wraps are also an important material to save both your brand and your product.

What Is A Clear Pallet Stretch Wrap?

As the name suggests, a stretch film wrap is a highly stretchable plastic film that is wrapped around items. It has elastic recovery properties, which enables the wrap to keep the items tightly bound. It is especially used to wrap products on a pallet. This helps to secure the products to each other and to the pallet itself. The pallet stretch wraps are available in a wide range of widths, thickness and types and can be used based on the need of a particular product. Therefore they help in reducing product loss and discourage load tampering. Moreover, a pallet that is secured with a pallet wrap highly reduces worker injury during the loading and unloading process. Although they are commonly used in unitizing pallets, at times they are used for bundling smaller items. There are several types of stretch film wraps like hand stretch film, bundling stretch film extended core , machine stretch film, static dissipative film and pallet netting stretch wrap.

However, before getting into the details of each of these stretch films, let’s dive in and know the materials used in the manufacturing of pallet stretch film wraps.

What Are Clear Pallet Stretch Wraps Made Of?

Linear low-density polyethene or LLDPE is the most commonly used material in the manufacturing of clear pallet stretch wrap. This material is produced by the process of copolymerization of ethylene with alpha-olefins, the most common that are hexene, butene and octene. When higher alpha-olefins like octene or hexene are used it enhances the characteristics of the stretch film. Particularly it enhances the properties of elongation at break and puncture resistance.

At times, other types of polyethene and PVC are also used to produce stretch film wraps. Many pallet films have about 500% stretch at the break. However, during usage, it is stretched only about 100-300%.

How Are Stretch Film Wraps Produced?

Stretch film wraps are primarily produced in two methods- the blown method and the casting method.

Blown method

In the blown method the plastic resin is initially melted and then extruded through an annular die. Later it is air-cooled. Although this process is slower it provides high-quality stretch wraps. However, based on the quantity that can be produced per hour, the cost of production of blown wraps are higher.

Casting method

In this method, the stretch film is extruded i.e., manufactured through a slot die. And then it is passed over cooling rollers. Therefore the process of cooling happens almost instantaneously. Although the quality of cast film wraps is not as good as the its cost of production is less. In this method, you can produce a lot more film wraps in an hour when compared to blown wraps.

What Are The Functions Of A Clear Pallet Stretch Wrap?

A clear stretch film wrap makes sure that the boxes on a pallet stay safely and well-aligned. This is especially important in warehouse distribution. In unitizing pallets, the stretch film wraps serve the following functions:-

- They help in forming a unit load by offering improved stability of packages or products.

- They also offer protection from dust and moisture.

- They extend the shelf life of certain food items.

- When used, they make the storage and handling of units easier.

- Some strict films, like the UV stretch wraps, offer a degree of sun protection. And so leaving the products out in open spaces need not be a problem anymore.

- They also offer tamper resistance and a degree of resistance to package pilferage.

What Are They Types Of Clear Stretch Film Wraps?

There are several types of stretch films out there in the market and each serves a unique purpose. Well, let us consider a few of them.

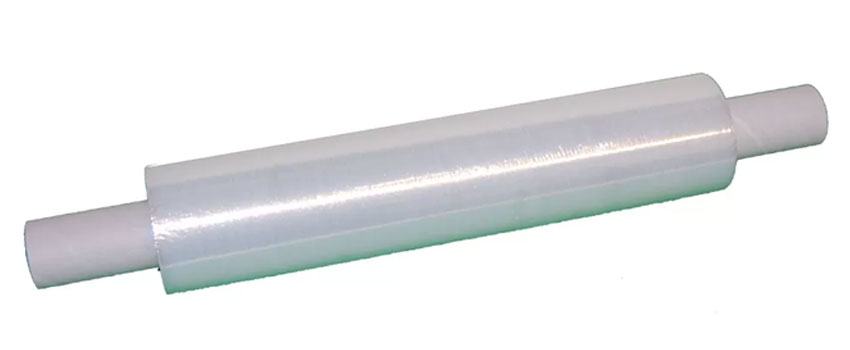

Hand stretch film

These wraps are stretch wraps that have to be applied manually. Therefore they require human power, both to wind and unwind them. They are smaller in size and width than the machine stretch films. It facilitates the person applying it to handle it with ease. They are excellent for low volume applications and are a cost-effective way to bundle up items. These are pre-stretched and so the person applying them, will not have to stretch them further.

Machine stretch film

The machine stretch films are always used in conjunction with a pallet stretch wrap dispenser machine. The machines work automatically, and therefore it saves a lot of time. When the parameters are set, it can wrap several pallets in a few seconds. As the pallet sits on the platform of the machine, it spins the pallet and applies the stretch film. On the contrary, a few machines have an arm that is used to rotate around the pallet and thereby apply the stretch film. It can be ideal for high volumes of load and will help in achieving a professional look.

Pallet Netting Stretch Wrap.

These are very similar to clear stretch film wraps in functions but are netted and therefore could be used on items that require ventilation. It can be ideal to be used on products that form condensation, that have to cure and cool down in a timely manner and on fresh produce that has to breathe. They are strongly knit to provide load stability and are highly recommended for the food industry.