When it comes to packaging and protecting your products during transportation, using the right Proper stretch film is crucial. Not only does it ensure the safety of your products, but it can also save your business money in the long run.

Choosing the right stretch film can be confusing, but with a little knowledge and understanding of the different types and applications, you can make the best decision for your business.

At Safe Packaging, we understand the importance of proper packaging and are dedicated to providing our customers with the highest quality stretch film products to meet their specific needs.

What is Stretch Film? & Types of Stretch Film

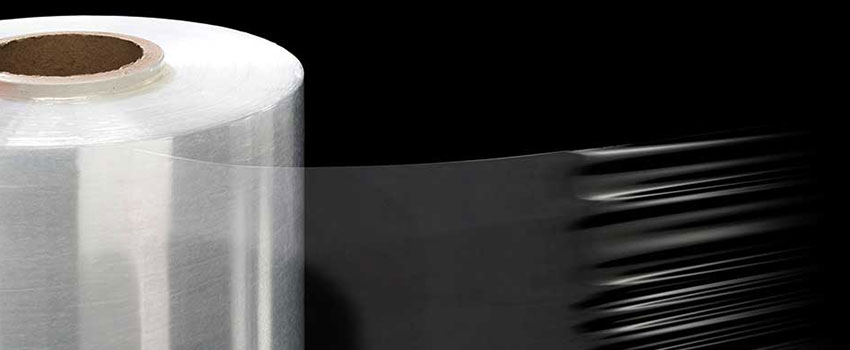

Stretch film, also known as stretch wrap, is a stretchable plastic film that is used to secure and bind items together. It is commonly used in packaging and warehousing to hold products or pallets of goods together during transport and storage.

Stretch film is made of linear low-density polyethylene (LLDPE) and is stretched when applied to the items being wrapped. The stretchability of the film allows it to conform to the shape of the items being wrapped, providing a secure hold while also protecting the items from dust and moisture.

Stretch film is available in a variety of thicknesses and strengths to suit different packaging needs and can be applied manually or with a machine.

Hand stretch film, also known as stretch wrap or pallet wrap, is a type of stretch film that is applied manually by hand. It is commonly used to secure and bind items together for transportation and storage. The film is made of linear low-density polyethylene (LLDPE) and is stretched when applied, allowing it to conform to the shape of the items being wrapped. This provides a secure hold while also protecting the items from dust and moisture.

Hand stretch film is available in a variety of thicknesses and strengths, including heavy duty options, to suit different packaging needs. Additionally, it has good transparency, tear resistance and high performance. Cast film is also one of the type of stretch film that it is produced by casting method and has similar properties to hand stretch film.

The first step in choosing the right stretch film is understanding the different types available. There are three main types of stretch film: cast, blown, and pre-stretch.

Cast Stretch Film

Cast stretch film is created by pouring melted resin into a chilled roll, which creates a thin, consistent film. This type of Proper stretch film is known for its clarity, strength, and ability to resist punctures and tears. Cast stretch film is often used for palletizing products and protecting them during transportation.

Blown Stretch Film

Blown stretch film is created by blowing hot, melted resin through a circular die, creating a thicker, more elastic film. This type of stretch film is known for its stretchability and ability to conform to irregularly shaped products. Blown stretch film is often used for wrapping irregularly shaped items or for securing products together.

Pre-stretch Stretch Film

Pre-stretch stretch film is created by stretching the film before it is wound onto a roll. This process creates a thinner, stronger film that can stretch further than traditional cast or blown stretch film. Pre-stretch stretch film is often used for palletizing products and protecting them during transportation.

Common Applications of Stretch Film

Once you understand the different types of stretch film available, it’s important to consider the specific applications for which you will be using the film. Different types of stretch film are better suited for different applications, so it’s important to choose the right one for your needs.

Palletizing

When palletizing products, it’s important to choose a stretch film that is strong and puncture resistant. Cast stretch film is often used for palletizing products as it is clear, strong, and resistant to punctures and tears.

Wrapping Irregularly Shaped Items

For wrapping irregularly shaped items, it’s important to choose a stretch film that is elastic and conforms to the shape of the product. Blown stretch film is often used for this application as it is more elastic and conforms to the shape of the product.

Securing Products Together

For securing products together, it’s important to choose a stretch film that is strong and stretchable. Pre-stretch stretch film is often used for this application as it is thinner and stronger than traditional cast or blown stretch film.

Tips for Choosing the Right Stretch Film

Product size and weight

When choosing a stretch film, it’s important to consider the weight and size of your products. For heavier or larger products, it’s important to choose a stretch film that is strong and puncture resistant.

Environment in which your products will be transported

Another important factor to consider is the environment in which your products will be transported. If your products will be transported in a cold storage or freezer environment, it ‘s important to choose a stretch film that is specifically designed for those conditions. This type of stretch film will be more flexible in cold temperatures and will not become brittle or crack.

Stretchability of the film

The stretchability of the film is also an important factor to consider. If your products are irregularly shaped or need to be secured together, it’s important to choose a stretch film that can stretch further and conform to the shape of your products.

Cost

The cost of stretch film is also an important factor to consider. While it may be tempting to choose the cheapest option available, it’s important to remember that the right Proper stretch film can save your business money in the long run by protecting your products during transportation and reducing the need for frequent replacements.

Recycling

Recycling is becoming increasingly important in the packaging industry, and stretch film is no exception. Many stretch films are made from polyethylene, which is a recyclable material. However, not all stretch films can be recycled, so it’s important to consider this when making your decision.

Dispensers

Using the right dispenser can make a big difference in the ease and efficiency of using stretch film. Hand-held dispensers are great for small jobs, while power pre-stretch dispensers are ideal for larger jobs and can save up to 50% on the cost of stretch film.

Color

Color can also play a role in the selection of stretch film. Clear stretch film is great for visibility and inspection, while colored stretch film can be used for identification and security. Stretch film can also be printed with custom designs and logos, which can be useful for brand recognition or product tracking.

UV Protection

UV protection is also an important factor to consider when choosing stretch film. UV rays can cause damage to your products and shorten their shelf life. UV protection can be added to stretch film to help protect your products from UV rays during transportation and storage.

Apart from these factors, it’s also important to consider the supplier of your stretch film. Make sure that the manufacturer is reliable, experienced and has a good reputation in the industry. A supplier with a good reputation will be able to provide you with high-quality stretch film that meets your specific needs and is backed by a solid warranty.

Get the Best Stretch Film at Affordable Prices

Choosing the right stretch film is crucial for protecting your products during transportation and saving your business money in the long run. By understanding the different types of stretch film available and the specific applications for which they are best suited, you can make an informed decision for your business.

At Safe Packaging, we are dedicated to providing our customers with the highest quality stretch film products to meet their specific needs.

Don’t compromise on the quality of your stretch film. At Safe Packaging, we can provide you with the best stretch film products for your specific needs. Contact us today to learn more about how we can help your business with all of your stretch film needs.