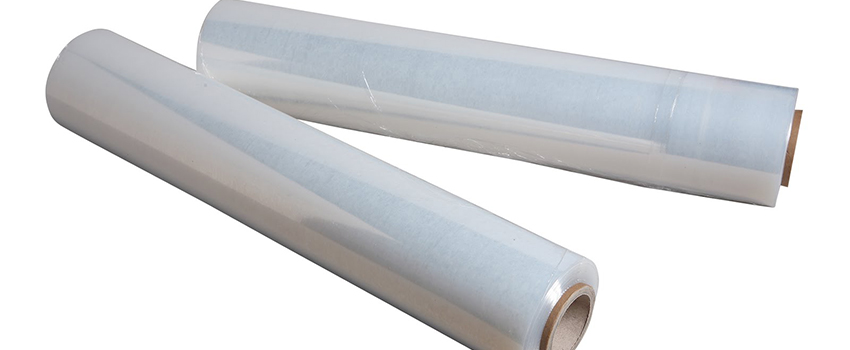

One of the most popular techniques for holding the products on your pallet is stretch wrapping. Stretch film, which is often constructed of polyethylene, is a thin, elastic-plastic sheet being used to connect and hold cased goods to a pallet.

This tension creates a constriction force all around the load that holds it in position as you extend and roll the pallet. This can assist in preventing product damage during transportation from improper handling, unforeseen movements, or problems brought on by the weather.

The top advantages of covering pallets in stretch film are listed below.

Advantages of Using Stretch Film

Safety

The protection it offers is among the benefits of utilizing stretch wrapping on your pallets. It helps avoid product fraud, accidents, and other problems by securing the products firmly tied.

Stretch wrapping offers many protection advantages, including:

- Stretch film shields objects from dust, moisture, and other contaminants.

- You can hide the contents of the load and lower theft by using transparent stretch material.

- UVI stretch sheets can shield your goods from Ultraviolet rays if you store them outdoors.

- Stretch wrapping makes your loads more secure, allowing you to reduce shipping damages and costs.

Efficiency

Stretch film wrapping will help you save big bucks if your company wraps pallets regularly because it will make employees more productive and reduce the risk of damage.

Among the ways stretch film might increase productivity are:

- Stretch film boosts workers’ productivity and packaging effectiveness.

- Enabling inspections enhances the inventory management system and is more energy-efficient than shrink-wrap systems.

- Generally speaking, stretch wrapping is less expensive than solutions like strapping and other types of pallet wrapping.

- the capacity to use opaque stretch films to color-code things.

Recyclable

In essence, most businesses are taking steps in the direction of sustainable practices. Unlike many other plastic products, stretch film wrap for pallets is recyclable and is categorized as a category 4 item in most programs. As a result, recycling stretch film is not only theoretically viable but also practical and affordable.

Top stretch film recycling advantages include:

- Stretch film can be recycled, therefore going green can have an influence.

- You may avoid tipping costs and perhaps gain a little money back by recycling.

When it comes to properly covering a pallet, stretch film has several advantages for your organization and can be environmentally friendly.

Stretch Film Are Very Useful

Stretch film may resemble heavy-duty cling film, yet it is one of your packaging arsenal’s most adaptable, practical, and affordable products.

Stretch film has a strong friction coefficient and is made to stick to itself without the usage of adhesives or fasteners. To put it another way, it efficiently holds itself in position once it has been folded over itself under pressure.

Stretch wrap film is typically used to wrap a cargo and stretch it into position to secure products on a pallet for shipping or warehouse storage. An “elastic band effect” keeps the weight firmly in place because the plastic has a memory and tends to shrink back to its original size.

Stretch film may thus be swiftly and readily stretched to loads of all forms and sizes. It also implies that removal is equally quick and simple; all that is required is a simple hand extraction after cutting down one corner to relieve the tension.

Almost every packing procedure might be made better by the wise use of stretch film because it can be used in a wide variety of applications across such a diverse range of industries.

Based on your unique requirements and application, it can also be utilized with manual hand-held devices, and semi-automatic, or automatic machines that are available in a range of grades, gauges, thicknesses, and colors.

Types of Stretch Film Wrap

If you’re looking to buy a stretch wrap, you should first decide what kind of wrap your operation requires. A general-purpose wrap might well be appropriate if numerous wrapping jobs need to be completed around the warehouse.

The greatest option if you’re working with electronics, is an anti-static wrap. A high-performance stretch wrap will provide the protection you need if you’re storing and transporting very precious or vital items.

The point is that there is a stretch wrap type that will meet your demands; you simply have to identify those criteria and then couple a particular stretch wrap to meet them.

Hand Vs Machine-Applied

There are forms of stretch wrap that can be applied manually and automatically, but not all sorts. Consequently, you must take both your needs and the length of your wrapping process into account.

A stretch wrap machine is beneficial for a hectic operation wrapping thousands of pallets every day, which calls for a machine-applied stretch wrap.

However, if there are fewer pallets, technology won’t be necessary; a hand-applied stretch wrap procedure will suffice, and anything more would be unnecessary.

Hand-applied stretch wrap

The process of hand stretch wrapping involves simply wrapping the stretch film all around items that require to be packaged. To provide a secure wrap and stable grip for storage and transportation, the appropriate pressure must be applied. Stretch wrap that is done by hand is made with the user’s needs in mind and has smaller, lighter rolls that are easy for a person to apply.

Machine-applied stretch wrap

Stretch wrapping by machine is substantially quicker, simpler, and more effective. For optimal load safety and minimal waste, it can offer a tighter, more reliable wrap. Stretch wrappers are available as fully automatic or semi-automatic models.

Looking for a Reliable and Optimal Stretch Film Solution?

Your business might be losing time and money by still wrapping pallets the old-fashioned way. Lacking the ideal stretch and wrap quality, the extra film is probably needed to complete the task.

Due to our ten-plus years of experience, we at Safe Packaging can rapidly identify your stretch wrap issues and suggest the stretch wrap solution your company needs. We can provide the ideal packing and shipping solution for all of your requirements, from our high-performance stretch wrapping to sturdy cardboard postal tubes and mailing tubes.

Contact our competent staff at Safe Packaging right away for detailed information on how we can assist. We are always happy to respond to your inquiries and would be delighted to demonstrate how a small change to your stretch wrap could have a profound impact.